Industry Projects Overview

Smart Diagnostics and Fault Rectification for Rail Maintenance

Rail systems are complex and comprise thousands of different interrelated elements of very different types. In case of any faults, it requires expert maintenance staff to execute many tests and search for probable root causes. This is a time-consuming task that depends on the knowledge and experience of maintenance staff. Therefore, a need to have a smart diagnostic tool that compiled through years of operation and learn all relations between failure elements, which in turn can provide information that guides maintenance staff in troubleshooting and thus accelerate recovery.

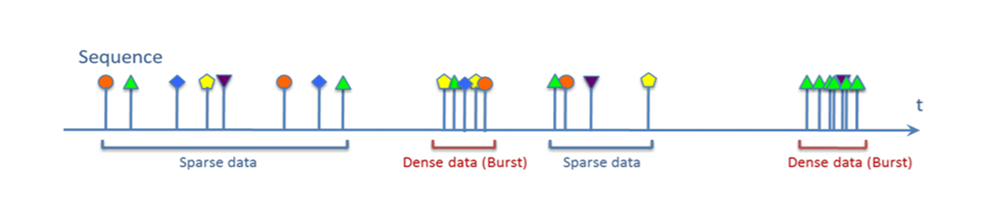

Events are being sent by sensors monitoring subsystems of diverse nature: passenger safety, lights, doors, etc. Many obstacles are to be considered and confronted, namely the rarity and redundancy of events (as shown in Fig 1). I had access to 5 years of past work order data which includes details like incident data & time, corrective action description. Similary 5 years of corresponding alarm codes data were also available.

Illustration of two types of events

Illustration of two types of events

I formulated the problem as a sequence classifier to recommend the problem, cause and remedy code for the given sequence of alarms. In this way, we not only consider the last alarm code as a reference for troubleshooting instead we consider sequence of alarms to cater the rarity and redundancy of events.

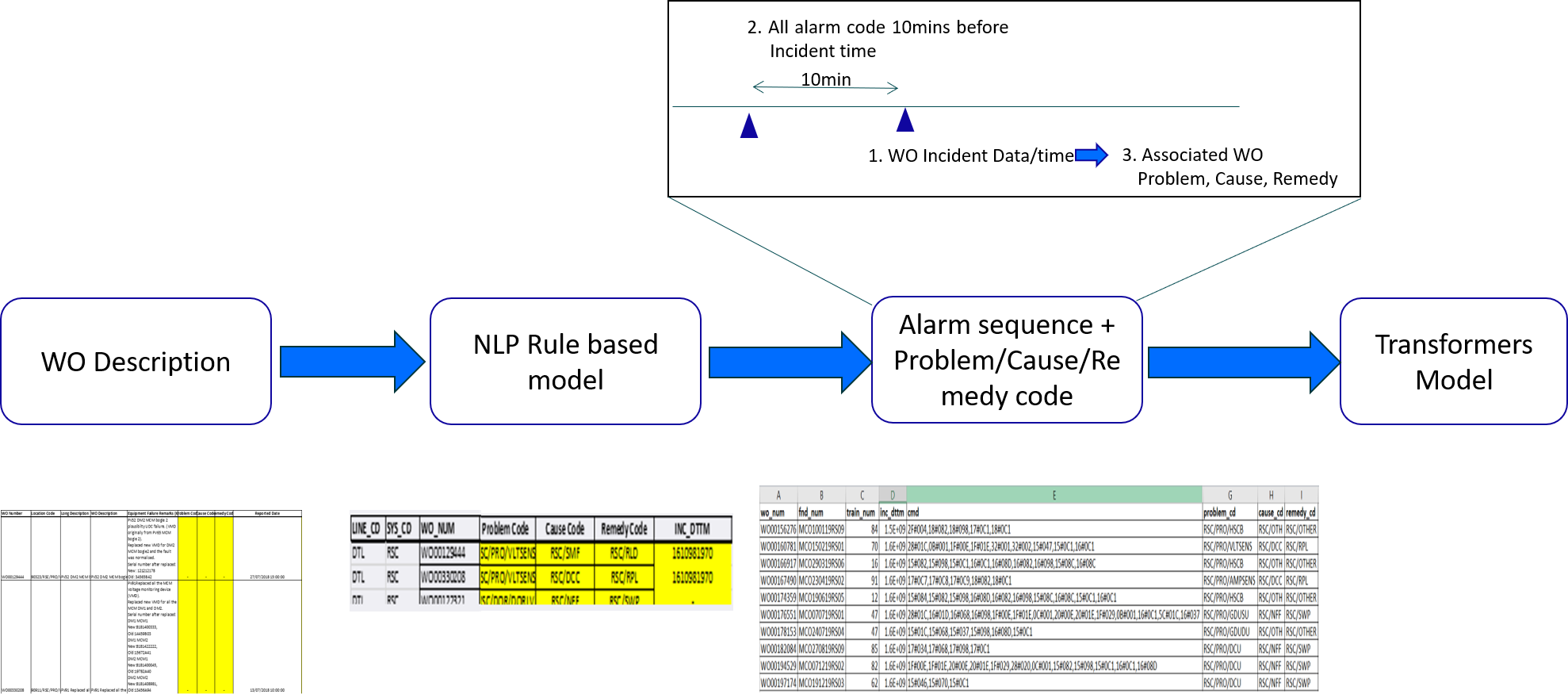

There were some data gap issues in particular the missing information of problem, cause and remedy codes in the work order data. As a work around, I applied a rule based NLP method (keyword matching) on the corrective action description to extract the relevant problem, cause and remedy codes for each work order. In total there were around 100 problem, cause and remedy code unique combinations. For sequence preparation, the alarm codes which are present within the window of 10 min from fault date & time are extracted.

Data transformation stages for sequence classification

Data transformation stages for sequence classification

Once the data transformation step is completed, the final dataset contains the alarm sequences and the corresponding problem-cause-remedy code for each work order. For the transformer based sequence classifier, the instances are alarm codes, tokenized into sequences of codes, and the classification labels are problem-cause-remedy code. The heart of the architecture is a large chain of transformer blocks. That is, the block applies, in sequence: a self attention layer, layer normalization, a feed forward layer (a single MLP applied independently to each vector), and another layer normalization. Residual connections are added around both, before the normalization. The output sequence is averaged to produce a single vector representing the whole sequence. This vector is projected down to a vector with one element per class and softmaxed to produce probabilities.

Transformers architecture for problem, cause and remedy recommendation

Transformers architecture for problem, cause and remedy recommendation

This piece of work has helped to save 30% of the rail maintenance time by accurate recommendations. Technicians now no longer have to travel to an asset in a far-flung location just to assess or troubleshoot problems, and sometimes they can even recommend a fix from afar. This tool can be built-in with events from power, communications, tracks, etc. to identify and rectify faults from external factors like track foundation movement, CBTC ,etc.

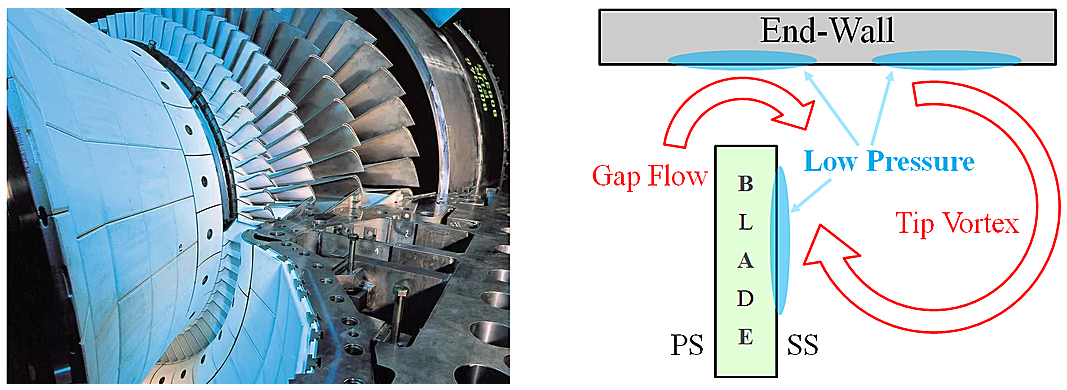

AI-Powered Physics-based Tip Clearance Prediction Method

Tip clearance is the distance between tip of rotating airfoil and stationary part. Such clearances introduces aerodynamic losses, decreasing gas turbine efficiency and degradation of blade tips.

During the design stage, the effect of tip clearance is measured by running lot of computer modelling and simulations. To impose design exploration at pace, lot of physics-based reduced order model were introduced. However, it involves lot of manual calibrations and requires substantial knowledge to get it work.

I devised a physics informed neural network to estimate the tip clearance dynamics. By taking into account the underlying physical model, allows to bound the space of admissible solutions to the neural network parameters. This translates the problem to a lower requirement in both the amount of training data and neural network size.

This innovative and creative work has helped to achieve the following

- Improved the solution quality of physics reduced order models.

- Accurate and systematic way to estimate tip clearance dynamics.

- Reduced the calibration time of physics reduced order model from 2 weeks to 2 hours.

Automated Defect Recognition in Fan Blade X-ray Images

Manufacturing of aeroengine fan blade involves lot of process. As one of the inspection process, the blades are X-rayed to identify defects. The inspections are manual and require several levels of scrutiny. One of the risk in manual process is that it can lead to potentially different standards of X-ray image analysis and sentencing being accepted.

Internal structure of aeroengine fan blade[2]

Internal structure of aeroengine fan blade[2]

I developed an Automated Defect Recognition (ADR) system equivalent to human information processing stage. I researched and formulated the defect identification problem as anomaly detection using GAN to address the following challenges in the current process (1) a smaller number of examples for each defect class, (2) disorganized defect logging process, and (3) prone to new defects. It builds upon by learning the normalcy of the images from the good images, reuse them to identify and locate the defects in a new X-ray image. In this way, we can quantify goodness and use that to identify any defect.

This piece of work has helped to save 10% cost of the overall inspection process. Also, demonstrated the capability that it can be read across to other visual inspection process where we are short of historical data for each defect class.

Automated Character Recognition in Turbine Blade Images

Jet engines are made up of almost 25,000 parts. Most of the parts are stamped with serial numbers to avoid mistakes in the production line and supply chain. In turbine blade corrosion level inspection process, the serial numbers are recorded to keep track of it. Each blade has a serial number and also it is engraved in the form of 2D data matrix.

Turbine blade with 2D data matrix code and serial number[4]

Turbine blade with 2D data matrix code and serial number[4]

The challenge here is that the blades after serving the engine, has lot of scratches and dirt on the surface which makes difficult to decode. I developed an OCR system to read the serial number from the given turbine blade images. It involves image collection, building dataset, image annotation, image augmentation, training the network and algorithm evaluation.

Character recognition or in general object detection has been an area of intensive research accelerated with deep learning. Character recognition can be achieved through two approaches.

- Region-Based detectors

- Single Shot detectors

I have implemented and evaluated the algorithms related to above mentioned approaches such as R-CNN, Fast R-CNN, Faster R-CNN, Yolo and SSD. The algorithm which worked well for this use case is SSD with an accuracy of 75%. Later, I improved the accuracy of the OCR system to 90% by using the computer vision algorithms and commercially of the system tools.

It has been succefully deployed in the factory which in turn improved the productivity from 1 batch to 8 batches per day. In addition, the setup of the OCR system has helped the inspection unit to made available information digitally with just 1 click of a button.

Automated Corrosion Level Detection in Turbine Blade Images

Mechanical erosion like pitting, cracking, and burning is the main form of damage to engine compressor and turbine sections, with corrosion usually reserved for the parts of the airplane in closest contact to the atmosphere. But there is one form of corrosion that exists in the blistering environment of a turbine engine hot section,and it is called sulfidation.

Deterioration of turbine blades caused by sulfidation[4]

Deterioration of turbine blades caused by sulfidation[4]

It falls to the service technician and inspector to collect and analyze the blade and physical evidence to determine the true condition and effect of protective coatings. Human inspectors manually rank the corrosion condition into different levels which is subjective due to un-controlled lighting and human error.

I developed sophisticated prediction models which can learn the relationships between the given image and the corrosion level by just using the pixel information. I evaluated several traditional machine learning algorithms. As a result, random forest yielded 91% accuracy.

This work has drastically reduced the process duration from 1 week to 1 day per batch. More importantly, the system has completely avoided the human errors by exhibiting a consistent and accurate results.

Automated Vortex Detection in Unsteady CFD Simulations

The formation of vortices in the surrounding fluid is used as one of the indicators for measuring the efficiency of aerodynamic system designs. Automated vortex detection methods are needed to facilitate the exploration of large scale turbulent fluid flow simulations. The local methods often use the notion of swirling fluid motion to identify the vortex and it is successful to some extent. However, this kind of methods requires informations such as location, orientation, direction, etc. As a consequence, it increases the computational time.

Vortex shedding behind a circular cylinder[5]

Vortex shedding behind a circular cylinder[5]

I formulated the vortex detection problem as a binary classification task. The underlying idea is to identify the vortex for any given CFD mesh point by just using the raw simulation properties. In this piece of work, I focused on four areas namely feature selection, feature extraction, handling imbalance data and algorithm selection. I came up with a vortex prediction model using recurrent neural network (RNN). As a result, it could able to predict vortices with 95% accuracy. More details can be found in [6].

This work has reduced the vortex detection process from 1 hour to 1 minute per snapshot. Also, demonstrated the capability that it can act as an enabling tool to enhance the understanding of flow feature patterns and also in facilitating the analysis of large CFD data.

References

- https://www.snugt.net/clearance-flow

- https://www.cleanpng.com/png-cfm-international-leap-boeing-737-max-aircraft-tur-5946458

- https://www.technifor.in/markets-and-materials/markets/aerospace-defence/marking-turbine-blades

- https://www.researchgate.net/figure/Examples-for-deterioration-of-turbine-blades-caused-by-excessive-temperature-of-the_fig1_279210009

- https://giphy.com/gifs/street-von-karman-adfcF43L8QgZW

- Rajendran, Vinod, et al. “Vortex Detection on Unsteady CFD Simulations Using Recurrent Neural Networks.” 2018 Fluid Dynamics Conference. 2018.